Client

V. Sattui Winery, St. Helena, CA

The Need

Continue serving visitors during a full-scale marketplace renovation.

The Solution

Modular kitchen and marketplace for uninterrupted guest service.

Preserving Operations During Major Renovations with Mobile Solutions

V. Sattui Winery, a beloved Napa Valley landmark, has enchanted visitors with its handcrafted wines, Italianate architecture, and picturesque picnic grounds since 1885. Producing over 60 wines exclusively sold on-site and online, the winery draws approximately 300,000 visitors each year. However, its marketplace, deli, and tasting room—originally constructed in the early 1970s—were in need of a significant renovation to elevate the visitor experience and expand the facility by 2,500 square feet. This update aligned with the winery’s 50th anniversary in 2025, marking an ideal time for a major refresh. Yet, closing the winery for construction posed substantial risks to guest satisfaction, staff retention, and revenue. Continuous operation was crucial.

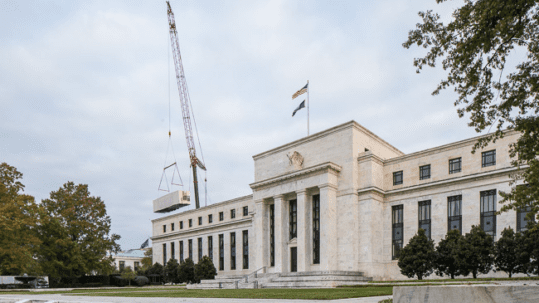

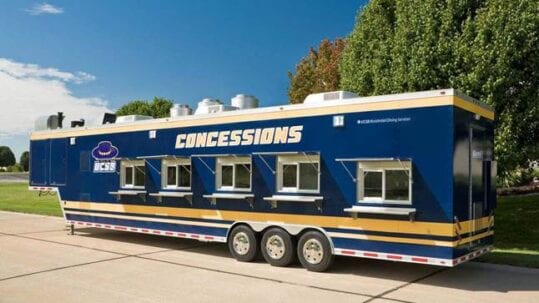

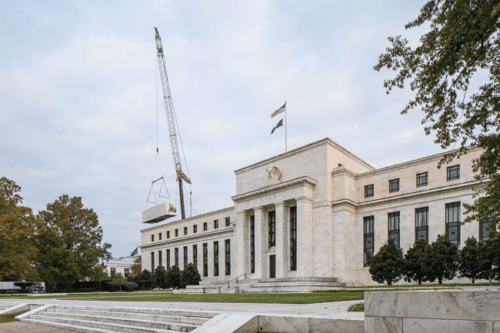

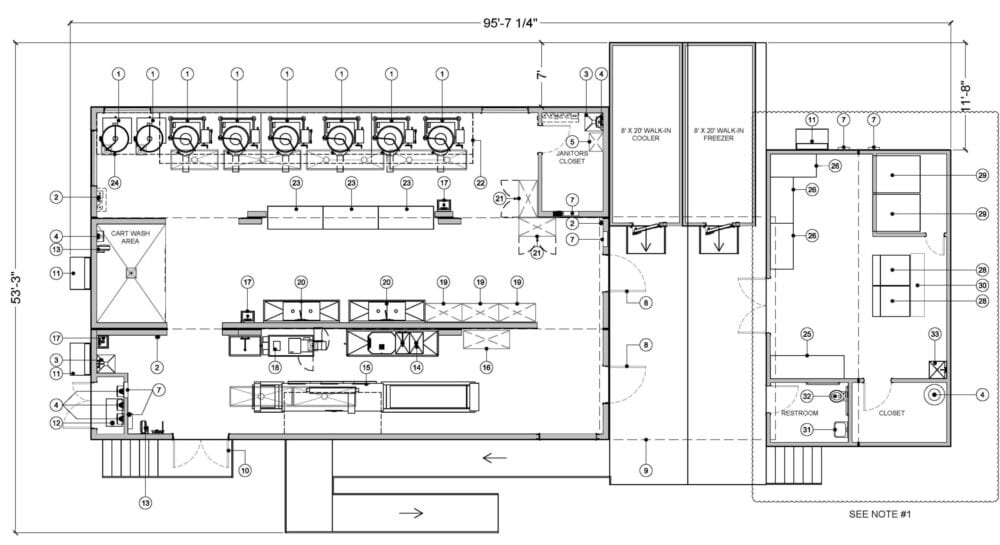

To keep operations running smoothly, V. Sattui Winery collaborated with Kitchens To Go (KTG) and our sister company, Mobile Modular, to provide a temporary kitchen and modular setup that would support the winery’s needs through the year-long renovation. The primary solution was a state-of-the-art mobile kitchen that allowed V. Sattui to continue offering fresh, on-site culinary experiences during the renovation. Additionally, a 36′ x 60′ modular building served as a temporary marketplace and tasting room, complete with ADA-compliant ramps and pathways, ample space for tastings, and food and wine sales. Located in shaded picnic areas, the temporary structures blended seamlessly into the landscape and maintained the rustic charm that visitors expect from V. Sattui.

Navigating the installation required extensive coordination with Napa County to meet local zoning and environmental standards. Every detail—from temporary utility connections for water, sewer, and electricity to the modular structures’ aesthetic integration—had to comply with regulatory requirements. The permitting process led to some delays, yet the V. Sattui team and our partners worked diligently to adjust timelines and modify the structures as needed to comply with county standards. These adaptive measures ensured that the modular facilities not only met operational needs but also provided a high-quality experience for guests.

With the high volume of visitors, the modular units and mobile kitchen had to be fully functional and immediately operational. Thoughtfully designed interiors, including original bars and displays, recreated the warm, inviting atmosphere of the winery’s tasting room. Initially, staff and guests were uncertain about the transition to modular spaces, concerned that the historic charm might be lost. However, the transformed interiors quickly put these concerns to rest. The layout facilitated smooth traffic flow, allowing guests to enjoy the same exceptional experience throughout the renovation.

The mobile kitchen played a pivotal role in ensuring V. Sattui could maintain its high standards in food service. This setup enabled on-site preparation of fresh foods, allowing the winery to deliver the diverse culinary offerings that are essential to the V. Sattui experience. The modular marketplace provided ample space for wine tastings and merchandise, enabling the winery to serve hundreds of thousands of visitors and keep operations nearly unchanged.

The mobile kitchen played a pivotal role in ensuring V. Sattui could maintain its high standards in food service. This setup enabled on-site preparation of fresh foods, allowing the winery to deliver the diverse culinary offerings that are essential to the V. Sattui experience. The modular marketplace provided ample space for wine tastings and merchandise, enabling the winery to serve hundreds of thousands of visitors and keep operations nearly unchanged.

By May 2024, the modular units were fully operational, enabling V. Sattui to preserve staff employment, accommodate visitor demand, and sustain business continuity. As the winery approaches its planned reopening in Spring 2025, the temporary modular setup has proven invaluable, preserving the guest experience and the winery’s reputation through this significant transition. V. Sattui’s project underscores the value of flexible modular solutions for high-traffic businesses, allowing them to maintain operations smoothly through major renovations. This successful project demonstrates how adaptable, quality-driven temporary setups can meet complex regulatory requirements and provide guests with exceptional experiences during times of change.

Kitchens To Go provides mobile, modular and containerized solutions for projects of any timeframe. Markets and conditions are changing constantly, however, so please connect with us to find out what options are currently available for your project’s need and timeline.