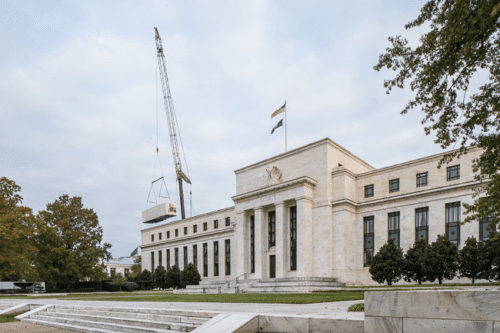

Client

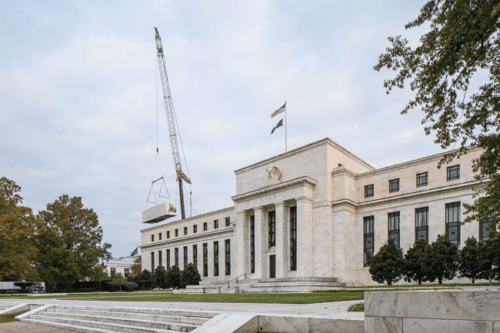

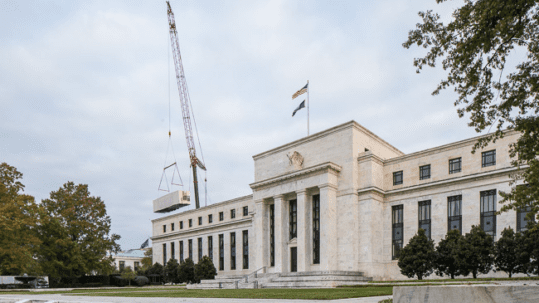

Federal Reserve Board, Washington D.C.

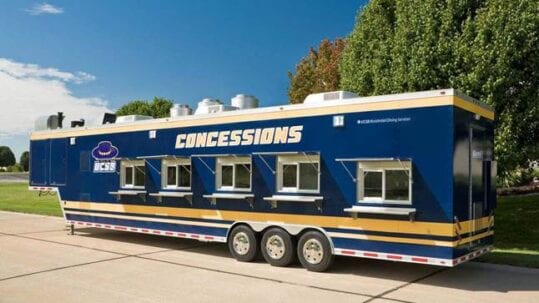

The Need

Interim Kitchen, servery and dining space needed during renovation.

The Solution

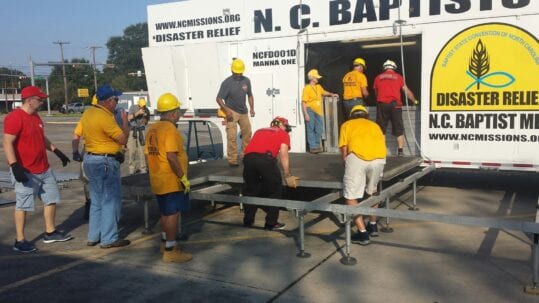

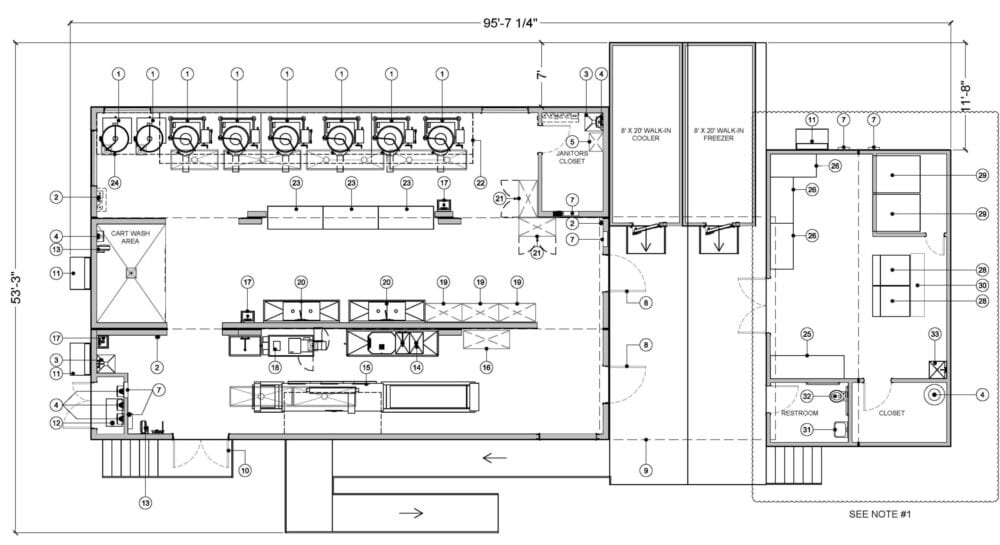

A six-module complex consisting of two Kitchen/Prep Modules with dock doors, one servery module, three dining modules, and one walk in cold storage unit.

project description

Extensive planning and permitting was required to place this six-module complex into an interior courtyard of the historic Eccles Building in the center of Washington, D.C.. A 550 ton crane was used to lift the modules over the building and then place them within eleven feet from the building and the courtyard fountain.

The lift took place between a Saturday and Sunday to minimize disruption to traffic and employees. The finishing kitchen, with integrated dock door and cold storage, allowed for ease of deliveries from both the commissary and suppliers. Due to the expected length of the project, 3+ years, the General Contractor opted to purchase the entire complex.

quick facts

- Food was prepped in the commissary and delivered to the interim kitchen to be finished on site.

- A 30’ storefront window wall overlooking the courtyard provided light and ambiance.

- The servery and dining space were designed to seat 60 guests.

Kitchens To Go provides mobile, modular and containerized solutions for projects of any timeframe. Markets and conditions are changing constantly, however, so please connect with us to find out what options are currently available for your project’s need and timeline.