CASE STUDY

Enhancing Hospitality Services: The Peninsula Hotel's Innovative Kitchen Solution

Le Petit Belvedere needed to maintain 5-star foodservice during the midst of kitchen renovations, and Kitchens To Go provided the hotel restaurant with the perfect mobile solution.

Le Petit Belvedere Restaurant, located within the Peninsula Beverly Hills Hotel.

To maintain 5-star foodservice to patrons during scheduled main kitchen renovations.

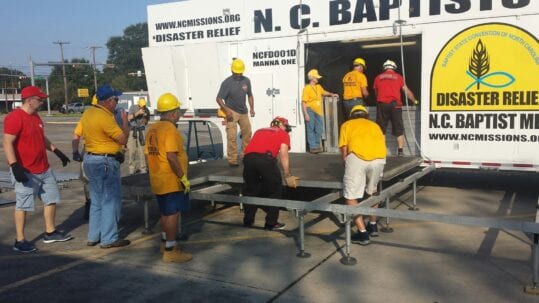

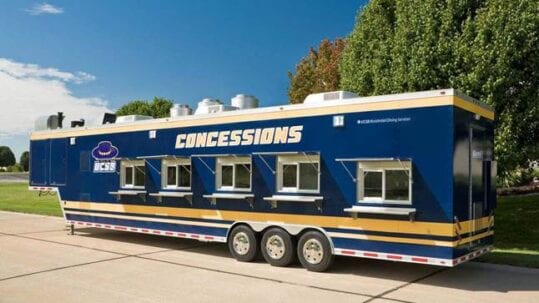

KTG provided three mobile semi trailers, with customized cookline equipment to mirror the restaurant’s kitchen.

project description

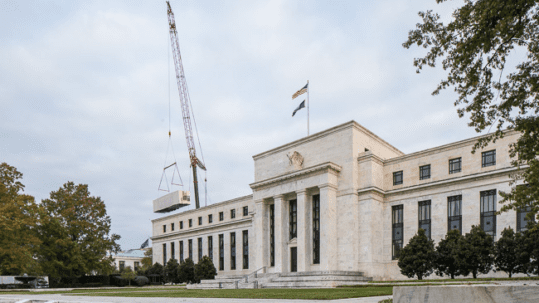

Le Petit Belvedere Restaurant, a staple of Southern California fine dining, approached Kitchens To Go for support during their 3-month facility renovation project. Located within the famed Peninsula Beverly Hills, and functioning as its sole foodservice production space, The Belvedere needed to find a way to continue service to the three other fine dining outlets located throughout the hotel complex.

To support their 5-star menus, which contained in excess of 500 items, Kitchens To Go designed a customized solution to mirror The Belvedere’s kitchen inside three trailers that would line up outside the hotel along busy S. Lasky Drive in the heart of Beverly Hills. These facilities fully ensured continuity of service with no interruption during the extent of the renovation.

related case studies

Connect with us.

Kitchens To Go provides mobile, modular and containerized solutions for projects of any timeframe. Markets and conditions are changing constantly, however, so please connect with us to find out what options are currently available for your project’s need and timeline.