KTG Receives 2012 Kitchen Innovations™ (KI) Award

Kitchens To Go, a leading provider of mobile and modular kitchen solutions, announced that the company’s Bolt-On Kitchen solution has been recognized by the National Restaurant Association with a 2012 Kitchen Innovations™ (KI) Award.

temporary or permanent, turnkey solutions

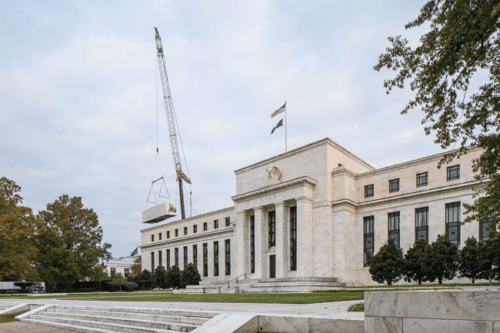

The solution, which was first introduced at the NRA’s 2011 conference, quickly gained traction with deployments in Massachusetts, Virginia, and Washington, D.C. In each instance, the commercial food service operations in these locations did not have the luxury of waiting the typical eight-months time that is usually required to gain permit approvals, design and then build a new kitchen on site. The Bolt-On Kitchen can be deployed in less than half this time, providing a high quality commercial kitchen solution that arrives on site and ready for installation and operation.

The Bolt-On Kitchen has also been deployed by the U.S. government. After completing construction of a new special events center at the Washington Naval Yard in Washington, D.C., it became apparent that there was a need for additional foodservice production. The only viable option to meet the requirements of the catering program and banquet rooms was to add kitchen space through a Bolt-On Kitchen. The exterior of the bolt on facility was constructed to match the exterior façade of the existing special events center, making it a seamless and attractive addition. A model of the Bolt-On Kitchen will be showcased in the interactive Kitchen Innovations Pavilion in its central location on the exhibit floor (booth 2440L) at the 2012 National Restaurant Association Restaurant, Hotel-Motel Show, May 5-8 at Chicago’s McCormick Place.

Kitchens To Go's Ralph Goldbeck receives the 2012 Kitchen Innovation Award from the National Restaurant Association's panel of independent judges during the conference.

How it works

Kitchens To Go’s Bolt-On Kitchen is a pre-constructed, code-compliant kitchen that may be affixed to an existing building on a permanent or lease-term basis, yielding savings over conventional construction costs. The Bolt-On Kitchen is a modular facility, which is joined to a permanent structure by a common sidewall, and is delivered with a custom-finished interior and exterior construction to match the existing building aesthetics and maintain the important brand image of each food service operation.related blog posts

Kitchens To Go provides mobile, modular and containerized solutions for projects of any timeframe. Markets and conditions are changing constantly, however, so please connect with us to find out what options are currently available for your project’s need and timeline.