Revitalizing Paradise: A Modular Solution for BP's Gas Station and Convenience Store

We're delighted to share our project supplying a modular convenience store for British Petroleum (BP) in support of the recovery efforts in Paradise, California following the 2018 Camp Fires.

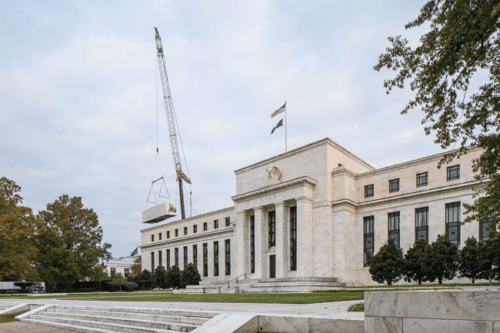

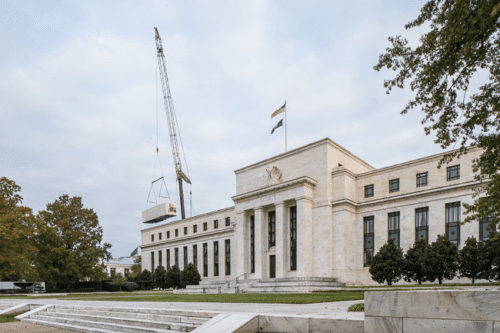

BP Modular Gas Station and Convenience Store in Paradise, California

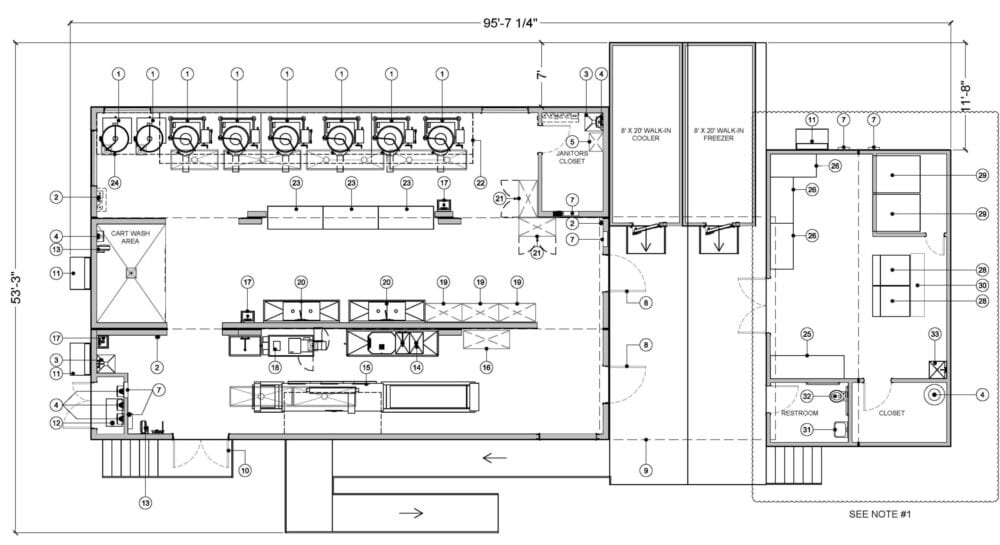

In April of 2020, BP commissioned Kitchens To Go to design and construct a permanent two-module facility to replace their convenience store that had been destroyed during 2018’s Camp Fire which ravaged Northern California’s Butte County and all but wiped out the town of Paradise.

Since the fire affected such a large area so significantly, the rebuilding process in Paradise had become slow in the months following the event, with costs skyrocketing and local construction teams in very low supply. BP reached out to Kitchens To Go to create a factory-built solution that could circumvent the significant costs, long timelines and local challenges that a site-built project would bring with it.

KTG’s facility was designed, built, transported and installed at the Paradise site in April of 2021 – just under a year from its commission – far quicker and at a better price point than comparable stick-built projects in the same area.

related blog posts

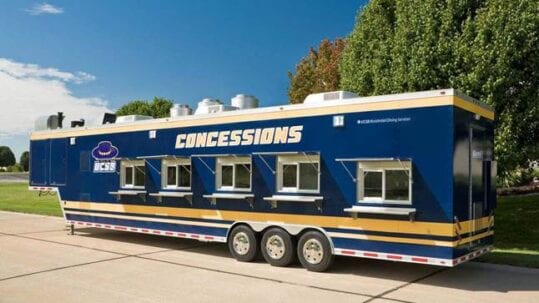

Kitchens To Go provides mobile, modular and containerized solutions for projects of any timeframe. Markets and conditions are changing constantly, however, so please connect with us to find out what options are currently available for your project’s need and timeline.